The process of homebrewing has a multitude of methodologies, each with its own set of proponents and detractors. Among these is the debate over the necessity, and indeed the merits, of boiling malt extract, especially when it comes from a beer kit. This article seeks to delve into the reasons why a brewer might choose to boil their malt extract and how to do it effectively, particularly when a hops schedule is part of the equation.

Traditionally, boiling is a critical step in all-grain brewing, serving multiple purposes: sterilization, enzyme deactivation, and flavor and color development. However, most malt extracts from beer kits have already been boiled by the manufacturer.

So, why would one consider reboiling?

One argument for boiling malt extract lies in the opportunity to layer additional complexity into the beer. Boiling can caramelize sugars, deepen flavors, and contribute to a stable finished product by reducing the risk of infection. It's an artistic touch that some brewers swear by, seeking to imprint a personal signature on a kit that might otherwise yield a predictably similar taste every time.

For those with a specific hops schedule in mind, boiling is non-negotiable. Hops utilization—the process by which hops contribute bitterness, flavor, and aroma to beer—is dependent on boiling. The alpha acids in hops need to be isomerized, a chemical process that occurs efficiently at boiling temperatures. If you've crafted a hops schedule, you'll need to boil to achieve the desired bitterness and hop character.

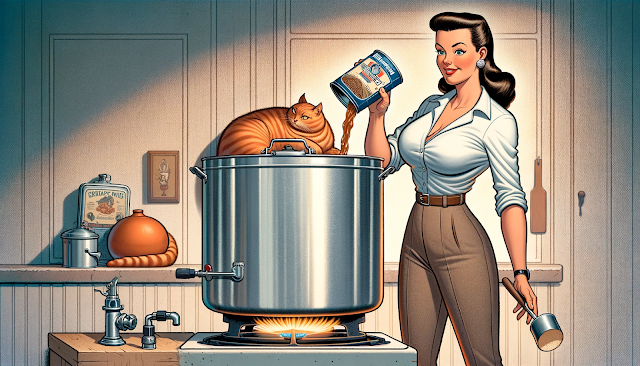

How to Boil Malt Extract from Beer Kits

Embarking on a malt extract boil is not a Herculean task, but it does require precision and attention to detail. Below is a structured approach to incorporating a boil into your beer kit regimen.

Preparing for the Boil

1. Equipment Check: Ensure you have a large enough pot to accommodate the boil and prevent boil-overs, which can be both dangerous and messy.

2. Water Volume: Start with a volume of water that will allow you to reach your target post-boil volume after evaporation. A good rule of thumb is to expect about 10-15% of volume loss to evaporation during a typical boil.

3. Malt Extract Addition: Add the malt extract to the water. It's advisable to do this slowly, stirring continuously to prevent scorching the extract on the bottom of the pot.

The Boil Process

1. Achieving a Rolling Boil: Bring your water and malt extract mixture to a rolling boil. This is a vigorous state of boiling that ensures maximum exposure for hops utilization and evaporation of unwanted volatile compounds.

2. Hops Schedule: Add hops according to your schedule. Typically, hops added at the beginning contribute to bitterness, while hops added in the last 15 minutes contribute to flavor and aroma.

3. Monitoring: Keep a close watch during the boil to prevent boil-overs and to ensure that your hops are added at the correct times.

Post-Boil Considerations

1. Cooling: Once the boil is complete, the wort must be cooled as quickly as possible to a temperature suitable for yeast pitching. Rapid cooling helps to minimize the risk of infection and can improve the clarity of the finished beer.

2. Sanitation: As always with homebrewing, sanitation is paramount. Ensure that all equipment that comes into contact with the wort post-boil is thoroughly sanitized.

3. Fermentation: After cooling and transferring the wort to your fermenter, it's time to pitch the yeast and let fermentation take over.

In conclusion, while boiling malt extract from a beer kit is not strictly necessary, it provides an avenue for customization and can be a rewarding experiment for the homebrewer. Whether you're seeking to personalize the flavor profile of your beer or to implement a particular hops schedule, a well-executed boil can elevate a standard beer kit to a craft of your own making. As with any brewing process, meticulous attention to detail and an adherence to sanitation practices will yield the best results.